At Avinton, we are committed to delivering Real AI to our customers and supporting their transition to data-driven enterprises. Our services do not end at the proof of concept, but we seamlessly integrate AI into practical applications used by real users in the real world.

AI Service Development

Empowering Business With

Real Artificial Intelligence

We have a track record of delivering projects using machine learning, deep learning, neural networks, computer vision, text recognition, and audio analysis across industries such as manufacturing, telecommunication, finance, and railway.

End-to-end support – ranging from AI consulting and data annotation to model training and application development – ensures that real business problems are solved. Not sure where to begin? Get started by reaching out to our AI consultants.

End-to-End Support From Consulting to Deployment

Consulting

Together, we define the use case. Sample data and overall requirements will be evaluated. Proofs of concept may be required if the feasibility is questionable. Avinton will propose a development timeline.

Data Collection

Data for training the model is collected. Existing data can be used or new data collected. Where difficulties arise in the acquisition of sufficient data, data augmentation may be considered.

Data Annotation

Collected data is annotated per use case requirements. In cases where domain expertise is required for the process, labeling techniques will be shared. Annotation can also be conducted by Avinton.

Model Training

The models are trained with annotated data and using the latest technologies. Using various neural networks and parameter combinations for training enables us to pick the best-performing model for deployment.

Deployment

Utilizing our Edge AI Camera solution, the tested models will be deployed on a nano-computer connected to optical devices. If required, the models can also be integrated with mobile applications (iOS/Android).

Case Studies: Artificial Intelligence in Production

Detecting Defects Within Thousands of IC Chips Inside Silicon Wafers

Silicon wafers consist of approximately 3,000 individual IC chips. We have developed an AI solution that can detect defects within these tiny chips. It will read an image of the entire wafer within seconds and detect abnormalities so small that they are undetectable to the human eye.

The benefits of this solution include a significant reduction in the time spent on quality inspections, as well as the removal of human error from the process. The fact that our customer was able to provide thousands of labeled images for the training of the AI model played a vital part in the success of this project.

The implementation of Avinton’s solution has resulted in a cut in manufacturing costs, improvements in product quality, and higher operational efficiency.

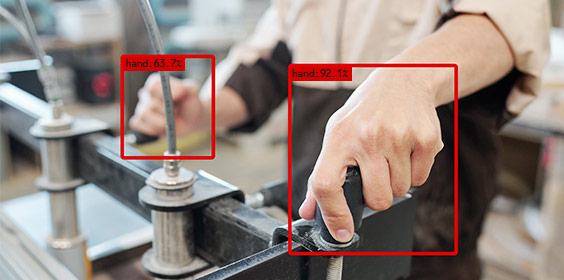

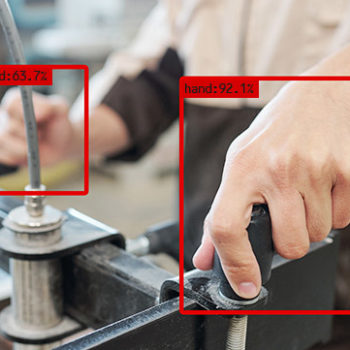

Securing Worker Safety At Manufacturing Plants in Real-Time

Manufacturing plants can be riddled with safety hazards – around every third fatal accident in Japan’s manufacturing industry is caused by workers getting caught in or between equipment.

At Avinton, we have delivered a computer vision-powered solution to a leading company in the field of printed products, industrial supplies, and electronic devices. The goal was to secure worker safety.

Optical devices powered by pre-trained AI models have been deployed throughout the factory floor. These devices detect body parts of workers entering areas of risk – for example, hands getting too close to open rollers, heavy machinery, or robots. The benefits of Avinton’s solution include the real-time monitoring of worker safety in cases where milliseconds matter.

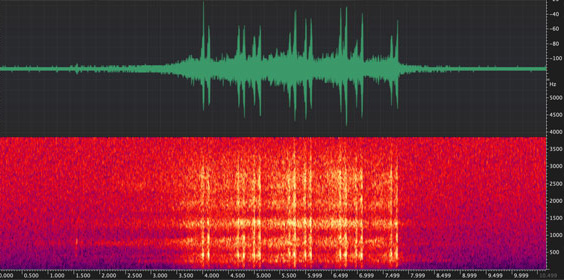

Detecting and Grading Railway Faults Through Audio Analysis (Sound AI)

Image recognition in the forms of object detection and image classification is what usually comes to mind when contemplating AI in production, yet audio is just as valid a data source. Due to many restrictions in place for placement on rail tracks, certain types of sensor data are extremely cumbersome to collect. So, when a particular railway company was looking to replace conventional systems to detect carriage faults, we introduced our Sound AI solution.

One of the main benefits of our solution is the ease with which audio data can be collected. Just from a sound recording, we are able to identify faults within the train bogie. We can even narrow this down to exactly which bogie and which component is at fault. This is indiscernible to the human ear.

Tool Management in Manufacturing Plants Using Computer Vision

Manufacturing plants tend to store maintenance tools in a centralized location. As tools left forgotten on the factory floor can pose a serious safety hazard, keeping track and ensuring all of them are returned, requires manual checks by workers.

Avinton has accomplished digital transformation for such customers by developing a mobile application. It utilizes computer vision to detect tools and integrates this process into the existing tool management workflows. The AI models can be replaced based on the specific tools used by each customer.

The benefits of our solution include workflow automation and elimination of human error through the removal of many manual processes.

Detecting Defects in Metal Structures With Object Detection

Large metal structures and scaffolds are prone to many forms of defects over time. Corrosion and loose fastenings pose a risk in safety and cause deterioration in operability. At the same time, manually checking each site is a time-consuming and expensive process.

We have developed AI solutions using object detection, capable of detecting defects from images or videos captured on-site. Our solution led to a significant cut in operation costs, as workers are no longer required to spend hours performing manual inspections.

Predicting Faults of Industrial Boiler Equipment With AI & Data Analytics

We analyzed the status of both the stable production and previous faults from time-series data collected from boiler equipment. Based on these insights, we established a system that can predict faults and initiate reports, enabling maintenance to be carried out before faults even occur.

Both traditional statistical methods and new machine learning approaches have been utilized in the automatic prediction of equipment faults, eliminating the need for manual monitoring and drastically reducing costs altogether.

Combining our experience and data analytics know-how with the domain knowledge of our customers has made this solution possible.

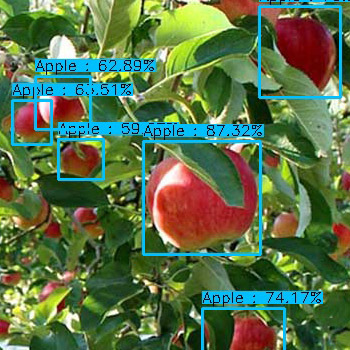

Counting and Forecasting Agricultural Yield With Object Detection & Data Analytics

Winds, frosts, heat – environmental influences are a major risk for farmers. A loss of harvest poses an enormous economic threat. IoT devices finally make “smart agriculture” a reality. These highly versatile and customizable devices can be equipped with cameras and sensors to gather information from fruit orchards, rice fields, tea fields, etc.

Counting fruit yields, for example, is time-consuming, costly, and inaccurate when performed by humans. Machine learning models take over and automatically count specific objects, from fruit to visitors to a facility or passing vehicles.

By training our AI models with already available data (historic weather or crop yield data, for example) and applying them to the newly collected sensor data, we can generate predictions about growth rate and yield. Utilizing our solution, farmers and large agricultural holdings can significantly reduce the cost of manual labor and the use of fertilizers, while increasing their crop yield and contributing to the nation’s aim for higher food self-sufficiency.

Human Detection and Tracking for Increased Safety and Security

Human detection is different from normal motion detection, because it triggers only when a real person is detected. Our camera-equipped edge devices are installed right on the location. The AI models then detect, track and count people in real-time.

Once triggered, a defined action (e.g. alerts or stop of machinery) is performed instantly. That way, improving safety and enforcing security becomes a fully automated process.

This functionality has proven especially useful for reporting unauthorized access of dangerous or restricted areas (e.g. on production floors, train stations, at residential buildings), for detecting or suspicious behaviour or accidents (e.g. falling of factory workers or patients in healthcare facilities), for traffic management (e.g. identifying popular routes of pedestrians in public areas), and for retail experience improvements (e.g. analyzing shopper behavior or dwell time).

Why Avinton?

Avinton has been handling data-orientated projects in various domains long before terms like Big Data and AI gained the degree of recognition that is seen today. Over half of the ongoing projects are focusing on Big Data and AI solutions for digital transformation purposes. Our dedicated blog article delves into the importance for companies to achieve enterprise-wide digital transformation.

All of our development is done in-house; we never use subcontractors. We have a team of engineers rich in both age and ethnic diversity, with proven expertise in various domains of IT. This enables us to answer specific requirements and deliver production-ready solutions of the highest quality and reliability.

For AI service development projects, our AI consultants carefully gather the requirements and coordinate the projects, AI engineers handle the training of optimal AI models, and our hardware and integration engineers will deploy the tested models to production environments.

We will be happy to provide you with more information.