Increase Efficiency & Safety With Customized Image Analysis

Make business intelligence a reality with our innovative Edge AI solutions. Let computer vision generate meaningful insights to meet new business challenges. Apply object detection and image classification right on the spot. Increase safety and efficiency where every millisecond matters.

Avinton Edge AI Camera is a highly versatile and fully customizable solution. It utilizes the latest technologies in IoT, machine vision, and edge computing. Accelerate your digital transformation process by turning visual data into business value.

Increase Efficiency & Safety in Factories

Improve Marketing at the Point-of-Sale

Manage Traffic & Public Transportation

Ensure Security in Public Spaces & Healthcare

So, what is Edge AI?

Most AI devices rely on a stable internet connection to the cloud at all times to complete tasks. But what if you are operating at the edge of the network? What if you operate in delicate situations in which every millisecond matters?

When it comes to ensuring safety and efficiency at manufacturing sites, telecommunications, in autonomous driving, or in public spaces, there cannot be any delay. That’s why Avinton’s Edge AI Camera delivers advanced image analysis and object detection technology locally and in real-time. At a fraction of the cost of conventional solutions.

Why Edge AI?

Edge AI enables complex tasks to be performed right on the spot – at high speed and low cost. Our solution is fully customizable to your needs and budget. The Edge AI Camera consists of a nano-computer on which the trained model is deployed. The device runs on low power and due to its small size, it can be placed inside existing equipment.

Fast

Where safety is at stake, milliseconds matter. Time lags are an inevitable consequence of AI processing in the cloud. With Edge AI the collection and inference of data are performed on the same device. That makes it up to 10x faster than cloud AI solutions.

Fully Customizable

Attach any USB / MIPI camera to suit your need and budget. Multiple cameras can be attached to the same hardware. Control switches, relays and environment sensors can also be integrated depending on the environment. All in all, the solution is highly customizable.

Highly Efficient

The device runs on low power, enabling it to be installed in secluded environments. Starting from 15W, it can also be powered by solar using battery backup. The nano-computer hosting the trained AI model starts at just the size of your hand. There is no need for securing a dedicated work floor space for the installation; the device can be placed inside existing equipment control boxes.

Low Cost

Whilst the one-time setup cost of Edge AI is just slightly higher, the long-term costs can be up to 8x lower than cloud-based solutions. The reason is that running heavy computation in the cloud can be very costly, especially if your device is running 24/7.

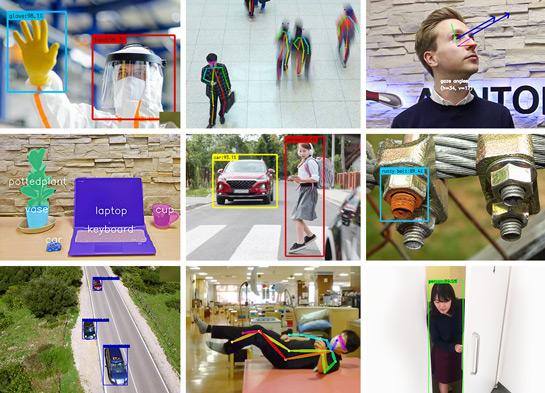

Ready-To-Use Features of the Edge AI Camera

While there are many hardware manufacturers and software companies out there, many only provide certain parts. At Avinton, we combine DX consultation and software development with AI and IoT device implementation. That way, we are able to deliver holistic and fully customized solutions.

So, whether it be to increase efficiency and safety on the shop floor or to improve marketing strategies, we will assess your individual requirements and prepare just the right AI model. Please find an overview of ready-to-use features below.

Object Detection

Object detection (classification and localization) is used to detect instances of semantic objects of predefined classes, whether it be people, vehicles, or pieces of equipment.

Defect Detection

Our AI camera can be trained to detect surface anomalies such as cracks, dents, or corrosion. The edge device, for example, can be placed on production lines to improve quality management.

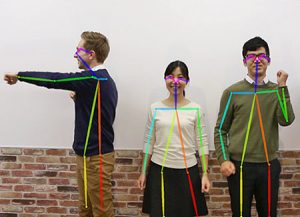

Posture Estimation

By detecting key feature points and connecting them, the AI model can estimate postures with high precision. Postures can indicate suspicious or potentially dangerous behavior.

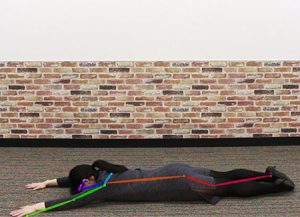

Fall Detection

Slips and falls are indicators of severe safety risks. By extending the capabilities of posture detection, this feature can increase safety in environments such as healthcare institutions.

Access Detection

Traditional surveillance cameras record footage to be monitored later. Our AI camera is trained to detect people and unauthorized access automatically and in real-time, greatly enforcing security.

Object Tracking

Our AI camera tracks the direction of moving objects and people. That way, visitor flows and popular routes can be identified, improving point-of-sale marketing or traffic management.

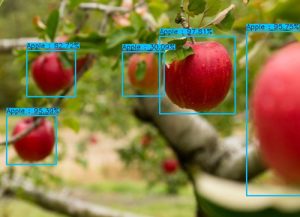

Object Counting

Counting objects manually can be time-consuming, costly and inaccurate. Our Edge AI solution keeps count of specific objects, whether it be visitors to a facility, passing vehicles, or fruit yield.

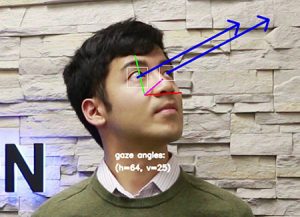

Gaze & Emotion Detection

A person’s direction of gaze can provide valuable insight into their point of interest, and their expression reveals their sentiment towards that object.

Hand Detection

As part of the object detection feature, a device running a model trained to detect hands can prevent potential injuries and accidents when using heavy machinery at manufacturing sites.

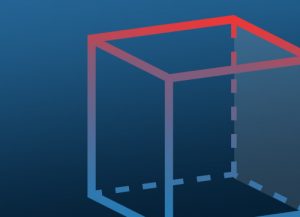

Depth Perception

We make use of the smallest depth-sensing camera on the market. This enables new robotics and logistics applications, such as volumetric measuring, gauging of objects, or 3D scanning.

Speed Detection

Machine vision with depth-sensing capabilities allows us to track the location and detect the speed of multiple objects. Increase safety in situations in which cautious movements are required.

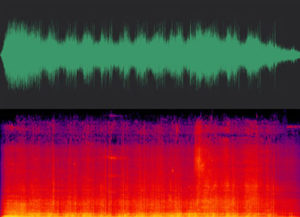

Sound Classification

Combining machine vision with audio analysis, we can detect faults in industrial machinery, and perform sound classification (e. g. bird recognition) or noise pollution analysis.

Introducing Depth Perception To the Edge AI Camera

Our AI solutions are fully customizable to meet our customers’ individual requirements – no matter if it’s in a smart factory, the telecommunications industry, agriculture, or a public space. By basing our development upon cutting-edge AI devices, we can offer unprecedented efficiency and accuracy.

We have recently added a state-of-the-art LiDAR camera to our AI service portfolio. Being the smallest high‑resolution depth-sensing camera on the market, it opens the door to new and innovative use cases. At just 100 grams per unit and a maximum distance of 9 meters, this LiDAR camera is highly flexible and suited for even the most complex tasks.

Logistics: precise volumetric measurement of objects

Robotics: gauging objects, or differentiating between objects on different layers

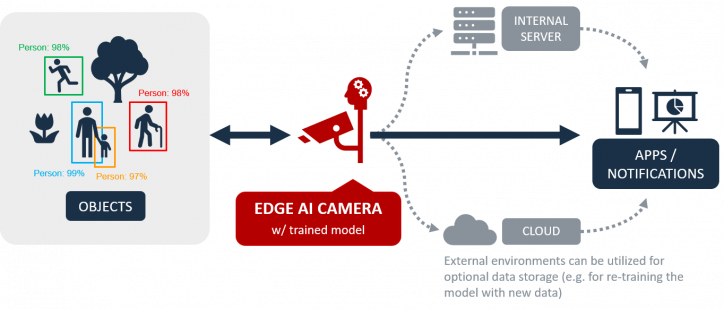

Edge Computing x AI x Machine Vision

With Edge AI, inferences can be made on the spot, paving the way for real-time business intelligence. AI is on-premise, unlike other options like Cloud AI where the model is secluded in a separate environment.

The solution can be applied to a wide range of real-world use cases, ranging from the securing of worker safety at production sites, to acquiring of customer attribute information for marketing purposes.

| Cloud AI | Edge AI | |

|---|---|---|

| Camera <> Cloud Bandwidth | High | None |

| Cloud Compute Cost | High | None |

| Scalability | Low (costly) | High |

| Running Cost | High | Low |

| Camera Cost | Low | High (but not by much) |

Edge AI Is a Game-Changer

The traditional approach to integrating AI with optical devices like a camera is through cloud computing. Data collected on-site is sent to deep learning models residing inside cloud-based data centers due to the need for heavy compute capacity. There is a reliance on network connectivity and stability since inference on the data is performed in a remote location.

The utilization of edge computing technologies brings AI to the very edge of the network i.e. the optical device itself. A nano-computer within the Edge AI Camera will host a trained AI model to perform complex tasks right on the spot – much faster and at a lower cost.

Use Case of the Edge AI Camera

Issue:

Worker safety at manufacturing sites

Accidents in the workplace are especially persistent in the manufacturing sector, and the number of incidents is on the rise. Cases, where parts of workers’ bodies are caught within heavy equipment, have severe consequences on the well-being of workers, and therefore the securing of safety is of the highest priority for any company.

Secluding areas of risk by fencing them off may actually increase the risk of workers getting caught in the equipment as their movements are restricted. The use of thermal sensors to detect workers near equipment was not a realistic option, due to the fact that they have protection clothing from tip to toe.

Approach:

Detecting workers with Edge AI Camera

Avinton’s Edge AI Camera has been fully tailored to meet the specific requirements of our customer. It is now in the process of being deployed in a leading company in the field of printed products, industrial supplies, and electronic devices. Specifically, it has been introduced to the manufacturing site of packaging for foods, beverages, household items, and pharmaceutical products.

When securing safety in manufacturing plants, milliseconds matter. That’s why we have been developing a system centered around the Edge AI Camera which detects both the hands and body of workers entering a pre-defined “area of risk” on the factory floor. Since the collection of data and its inference are performed on-site, there is hardly any time lag being generated within the process.

FAQ

Find answers to some frequently asked questions about the Avinton Edge AI Camera.

Why are the long-term costs of the Edge AI Camera so low?

Running heavy computation in the cloud can be very costly, especially if your device is running 24/7. In our sample calculation, the one-time setup cost of Edge AI was slightly higher than for Cloud AI. However, the long-term running costs of Edge AI were significantly lower.

Please note that these estimations are based on our sample calculation. For information about your specific use case, please get in touch with us.

Why is Edge AI much faster than cloud-based solutions?

Cloud-based solutions depend on a network connection. Even if this connection is stable and fast, the data first has to be encrypted and transferred to the cloud where processing and inferences take place. Once completed, the data needs to be transferred back to the device and get decrypted. Naturally, this process takes time. In our test, it took 490ms.

Edge AI, instead, performs intelligence right on the device and in real-time. In our test, it only took 53ms.

Please note that these estimations are based on our demo test and experience. For information about your specific use case, please get in touch with us.

Why Avinton?

Avinton has been handling AI- and DX-related projects in various domains, from manufacturing to pharmaceutics. Our strength lies especially in the integration of AI with machine vision, as encapsulated in our Edge AI Camera solution.

All of our development is done in-house; we never use subcontractors. Therefore, we are confident that the solutions delivered to our customers are always of the highest quality and reliability.

We have a team of engineers rich in both age and ethnic diversity, with expertise in various domains of IT. This enables us to tailor our solutions to individual customer needs, and integrate them into production-ready systems.

We will be happy to provide you with more information.